Introductions to Deep-pit Hotel

These seemingly "unprecedented" problems, such as waste rock crater, minus 65 meters depth, rainstorm pouring, cliff construction, anti-M9 earthquake, are the true portrayal of Deep-pit Hotel project.

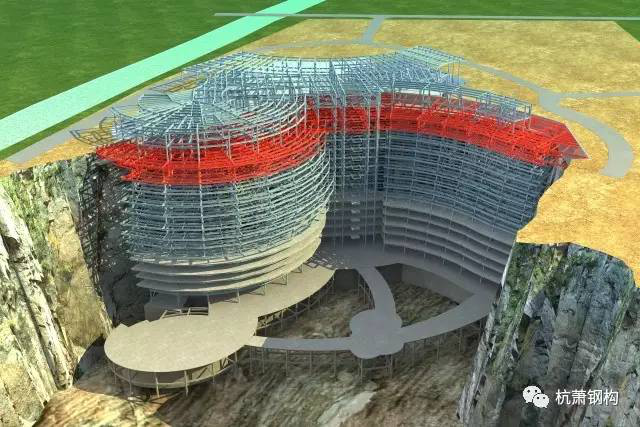

Deep-pit Hotel, as the lowest hotel in the world, was designed by the original crew of Burj Al Arab Hotel - Atkins team. China Construction Eighth Engineering Division acts as the general contractor of the project. Among them, the steel structure works, as an indispensable component of the whole project, feature M 9 earthquake resistance, special shape steel structure correction, measurement, installation, etc., which will make the builders not only think hard about the technical scheme at sleepless nights, but also control the time of the steel structure part in the whole process of the whole project, check the quality of every steel structure, and smoothly realize every link and so on.

In the face of such challenges, a domestic steel construction leader who has never retreated - Hangxiao Steel Structure was awarded the construction of this steel structure project. It not only solved the difficulties one by one that followed, but also bought valuable time and international construction standards for the whole project.

The company is determined to achieve with "intelligence" and become a "dancer" on the cliff pit wall

With unique arc pit wall environment, the major structure of Deep-pit Hotel is also designed to arc. This raises higher requirements for hotel steels both in strength and quality.

Hence, Hangxiao Steel Structure, with various production lines (H-shaped steel, steel truss floor plate, high-frequency welding, CCA plate) and strict product quality management, established QC quality management team through TOC management philosophy to optimize the site construction and installation scheme, shorten the construction period and achieve the purpose of fine management on the premise of ensuring the safety and quality.

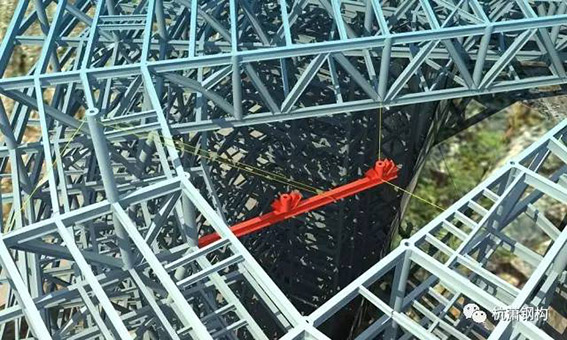

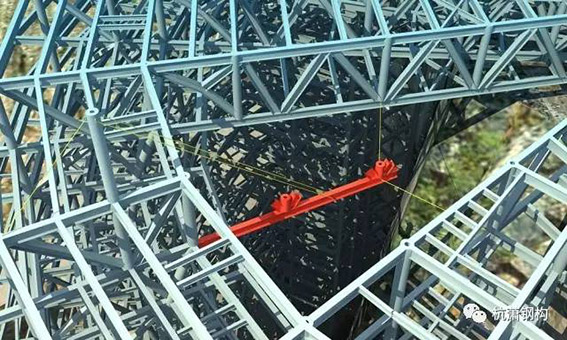

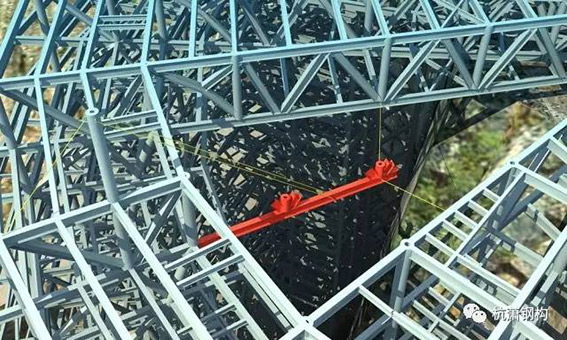

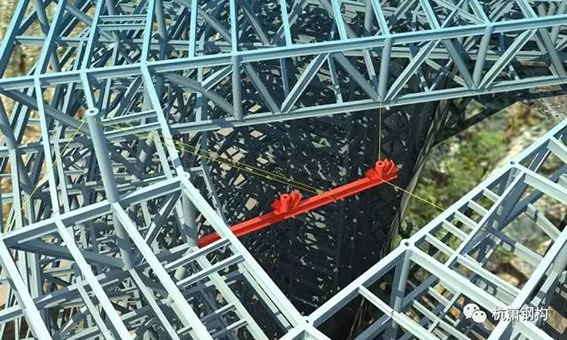

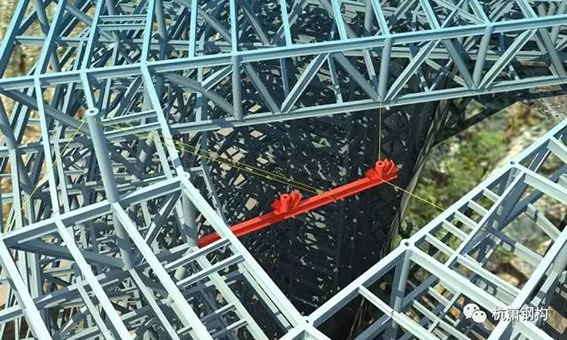

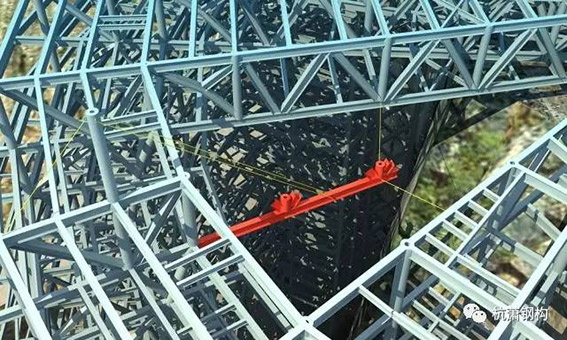

There are 30 large trusses in the first basement of this project. The truss height is 5m, the section of truss chord is 700*400*25*28mm and the span is 9m-31m. The truss runs across the main tower and pithead inside the pit. One end is connected with the main structure in the pit, the other end is connected with the pit roof foundation through the seismic support. The deadweight of single truss is 6.8t-31.8t. Because of the small bearing capacity of the ground foundation at the edge of the crater, and the difficulty of large crawler hoisting, a series of difficult problems such as the force on cliff pit wall, hoisting, closing, pulling force of wire rope, etc. occurred. After team design, overturn, replanning, and then overturning, and repeated simulation checks, the original three-stage installation was eventually adjusted to two-stage installation. One is to help reduce the number of sections, shorten the duration; the second is to avoid the risk that the roof shear wall which may be damaged by the cantilever truss; The third is to better control the deflection of the truss. The installation process is as follows:

Step I: Hoist the lower chord of the first section and pull the wire rope

Step II: Hoist the upper chord of the first section and pull the wire rope

Step III: Fill the first section of the web in turn, and construct the cantilever section of the column

Step IV: Hoist the lower chord of the second section

Step V: Hoist the upper chord and bearing stand of the second section

Step VI: Fill the second section of web in turn to complete the installation of the entire truss

When most construction units have to solve the problem of how to transport personnel and materials and equipment upward, the construction of Deep-pit Hotel will require a new challenge of "transporting the materials and personnel downward" for Hangxiao Steel Structure.

International advanced welding robots, assembly robots and other "intelligent" hardware advantages, which have been already owned and introduced, are also vividly displayed on the new stage.

The different "construction stage" becomes a unique skill with super - strong cohesive force

In terms of Frankfurt Airway Center, Hangxiao Steel Structure once faced a high degree of recognition from the German team known for its rigor; The first super-high-rise Babylonian square with steel structure in Malaysia is evidence of the strength and unity of Hangxiao Steel Structure team; Qingao Hotel in Georgia has won the acclaim of all the partners with the short construction period, high quality construction.

In terms of Shanghai Deep-pit Hotel, Hangxiao Steel Structure stood out and won the bid in many competitors, proving the company's advancement and advantages from technology to management. The management of Hangxiao Steel structure is not only to enhance productivity, but also to form a joint effort between different departments from the design department to the business department, so as to provide the best solution for the customers. In the whole construction process of the steel structure, from the initial anchoring of the steel structure to the installation of the steel column, the installation of the main structure, the construction of the truss and the construction of the steel structure, the company has made concerted efforts to overcome difficulties.

This is the outstanding achievement of solidarity and cohesion, which is the result of the experience of domestic and foreign projects.

When 28 academicians from the Chinese Academy of Engineering and Academy of Sciences visited the construction site of Deep-pit Hotel, the high praise became the driving force for everyone to move forward firmly.

Previous:Jiangxi Hangxiao Has Passe…

Copyright © 2021 All rights reserved: :Hangxiao Steel Structure Co., Ltd ICP:ZHE ICP 14001958

Phone:(+86) 0571-82645988

(+86) 0571-87246788

(+86) 0571-87248960

Email:globalbusiness@hxss.com.cn

hx@hxss.com.cn

Address:2826 Xiaoqing Avenue, Xiaoshan District, Hangzhou City, Zhejiang Province, China 311232